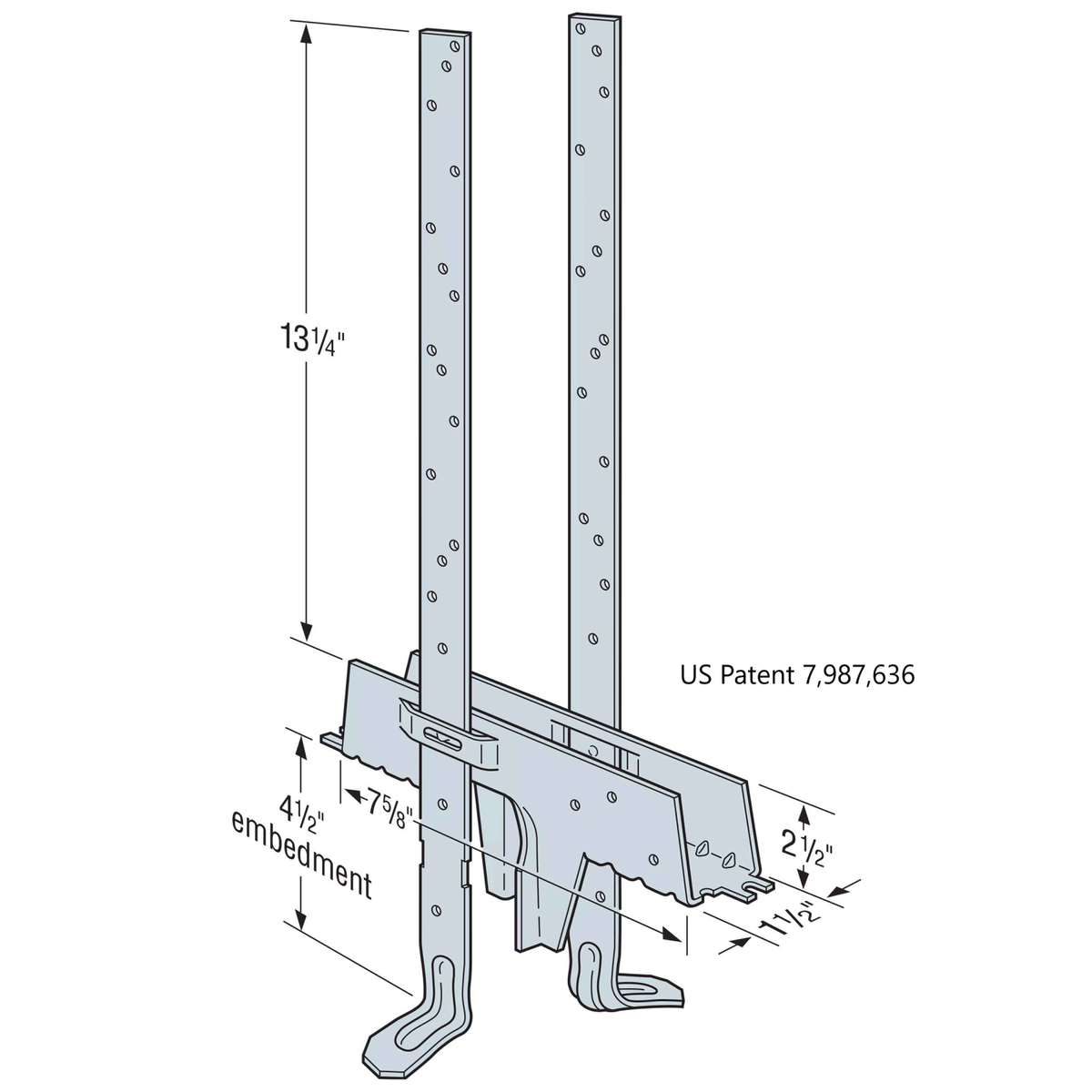

Simpson DETAL20 15 3/4 Dual Embedded Truss Anchor – G90 Galvanized Simpson Strong-Tie

$ 10,70 $ 6,42

The Simpson DETAL high-capacity embedded truss anchor combines dual embedded anchors with a structural moisture-barrier seat that serves to protect the truss and also provide additional lateral and uplift capacity. This anchor provides an engineered method to attach single-ply trusses securely to concrete and masonry walls. The embedded anchors of the DETAL are preattached to the moisture barrier through slots that allow some adjustment during installation to avoid rebar.

Installation :

- Tabs at each end of moisture-barrier seat, for optional attachment to the form board in concrete tie-beam applications.

- Strap can be installed straight or field-bent around truss or rafter members and is load rated for wind and seismic forces.

- Installed centered and flush on top of an 8″ masonry bond beam or concrete tie beam. The moisture-barrier seat bears on masonry face shell or concrete tie beam form boards; the two flanges embed into grout or concrete. The two embedded anchors shall be installed vertically into grout or concrete.

- For mislocated truss anchors which are greater than 1/8″ but less than 1 1/2″ from the face of the truss, a shim must be provided. Shim design by truss engineer. When gap is greater than 1 1/2″, abandon existing embedded truss anchor and install new anchor per designer.

- For lateral loads listed, the lowest four nail holes must be filled.

- Minimum spacing between the anchors to achieve full load is twice the embedment (Embedded 4 1/2″).

- In double anchor installations, install anchors with spoons facing outward and straps spaced no more than 1/8″ wider than the rafter/truss width. Do not install nails where the straps overlap when wrapped over the rafter/truss.

- Straps don’t need to be wrapped over the rafter/truss to achieve tabulated loads, unless noted.

NOTE: The correct fasteners installed in the correct position must be used to achieve published load values.

California Residents: WARNING

Prompt Delivery and Professional Packaging

Our long-standing partnership with UPS FedEx DHL and other carriers around the world lets us offer an array of shipping services. Our warehouse staff is extremely skilled and will package your goods in accordance to our precise and exact specifications. Your products will be subjected to an extensive inspection and be properly packaged prior to being shipped. Each day, we ship to thousands of customers in many countries. Our dedication to becoming the biggest online retailer worldwide is demonstrated by this. Warehouses and distribution centers are found in Europe as well as in the USA.

Note: Orders containing multiple items will have a separate processing time for each item.

Prior to shipment, we inspect the ordered items thoroughly before sending the items. The majority of orders are shipped within 48 hrs. Expected delivery times are between 3-7 days.

Returns

Due to multiple entities, including the factory and the warehouse, we are unable to fully manage stock. The actual stock can be changed at any time. It's possible that the stock may run out after the order has been made.

Our policy is valid for 30 days. If you haven't received your item within 30 days, we're unable to offer either a return or exchange.

To be eligible for a refund your item must be in good condition and in the same condition as you received it in. It must also be returned in the original packaging.