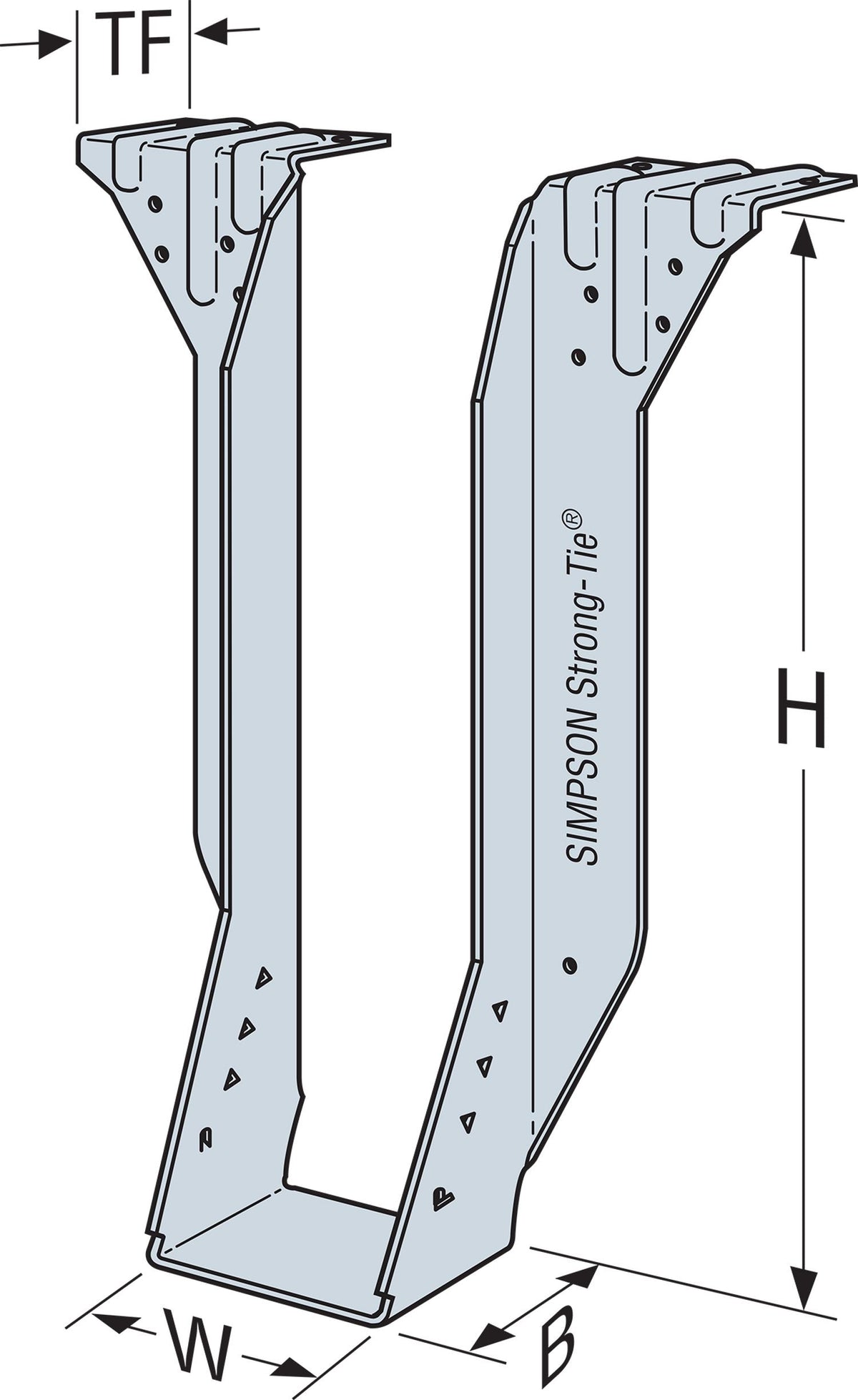

Simpson BA212-2 Beam Hanger, 12 Gauge – G90 Galvanized Simpson Strong-Tie

$ 24,74 $ 14,84

The Simpson Strong-Tie BA hanger is a cost effective hanger targeted at high capacity I-joists and common Structural Composite Lumber applications. A min/max joist nail option gives dual use of this hanger. Minimum values featuring positive angle nailing are targeted at I-joist without web stiffeners requirement and the maximum nailing generates higher loads to support structural composite lumber. The unique two level embossment provides added stiffness to the top flange. The Strong-Tie BA212-2 top flange hanger features a G90 galvanized finish for added corrosion resistance and requires the use of hot-dip galvanized fasteners which meet the specifications of ASTM A153

Installation:

Use all specified fasteners.

- LBV, B, BA and HB may be used for weld-on applications. Weld size to match material thickness (approximate thickness shown). The minimum required weld to the top flanges is 1/8″ x 2″ fillet weld to each side of each top flange tab for 14 and 12 gauge and 3/16″ x 2″ fillet weld to each side of each top flange tab for 7 gauge and 10 gauge. Distribute the weld equally on both top flanges. Welding cancels the top and face nailing requirements. Consult the code for special considerations when welding galvanized steel. Weld on applications produce the maximum allowable down load listed.

- B and HB hangers require the use of web stiffeners. BA MIN nailing does not require web stiffeners. BA MAX nailing requires the use of web stiffeners.

- Ledgers must be evaluated for each application separately. Check TF dimension, nail length and nail location on ledger.

NOTE: The correct fasteners installed in the correct position must be used to achieve published load values

California Residents: WARNING

Prompt Delivery and Professional Packaging

Our long-standing partnership with UPS FedEx DHL and other carriers around the world lets us offer an array of shipping services. Our warehouse staff is extremely skilled and will package your goods in accordance to our precise and exact specifications. Your products will be subjected to an extensive inspection and be properly packaged prior to being shipped. Each day, we ship to thousands of customers in many countries. Our dedication to becoming the biggest online retailer worldwide is demonstrated by this. Warehouses and distribution centers are found in Europe as well as in the USA.

Note: Orders containing multiple items will have a separate processing time for each item.

Prior to shipment, we inspect the ordered items thoroughly before sending the items. The majority of orders are shipped within 48 hrs. Expected delivery times are between 3-7 days.

Returns

Due to multiple entities, including the factory and the warehouse, we are unable to fully manage stock. The actual stock can be changed at any time. It's possible that the stock may run out after the order has been made.

Our policy is valid for 30 days. If you haven't received your item within 30 days, we're unable to offer either a return or exchange.

To be eligible for a refund your item must be in good condition and in the same condition as you received it in. It must also be returned in the original packaging.